Lean Principle & Forms of Waste..

- Get link

- X

- Other Apps

LEAN PRINCIPLE & FORM OF WASTE

- We Will Discuss below Topics Today

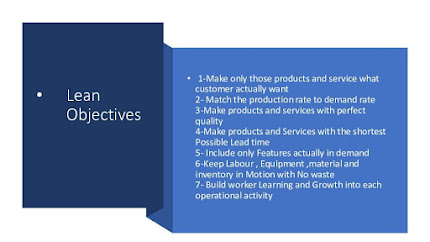

- Lean Principle & Objective

- Eight Form of waste

- Muda , Mura ,Muri

- My Favorite ( JIT) - Just In Time

- Takt time

Before starting today Discussion - All above mentioned topics will Lead you towards one Concept & That is " Improvement of Business process & Intent to decrease Process variation & Improve Customer Satisfaction"

Above topics are Tools which will lead toward above mentioned resultant.

Lean - A philosophy of production that emphasizes the minimization of the amount of all resources (Yes, Including the Time) Used in various activities of the enterprises. it involves identifying and elimination non value added activities in design, production, Supply chain management and dealing with customers.

It Contains a Set of Principles and practices to reduce cost and removal of waste and simplify all Process (Manufacturing & Support ).

Lean matches Supply with demand by providing only what is in demand and only at the rate it is demanded. This Might mean slowing production when demand slows.

This set the pace for Logistics activities also. Logistics professional are empowered to match customer service to customer priorities eliminating unnecessary service feature.

Lean = Non Valve added (Definition of waste)

Eight Form of waste :

- Transportation - Excessive Movement of People, Things Or information

- Inventory - Storage of Materials prior to Demand signal

- Motion - Unnecessary handling , walking, driving, bending, lifting, reaching

- Waiting - Idle time caused by lack of direction, instructions, information, parts or Equipment

- Overproduction- Make more than Immediately required

- Over processing - Higher grade materials or tighter tolerances than required

- Defects - Scrap , rework & erroneous Documentation

- Skills - Worker Underutilization or empowerment Beyond Capabilities

Four Elements of JIT ::

- HIGH QUALITY PRODUCTS (ZERO DEFECTS)

- Get link

- X

- Other Apps

Comments

Post a Comment